Ship Inspection

Planys conducted underwater inspection (In-water Survey/UWILD) for a large ship in South India of a port wall/dock at a major port in West India. Detailed visual inspection of underwater parts of the vessel during its berthing position was performed to avoid a dry-docking.

Scope of Work: Underwater visual inspection of hull, rudder, propeller, anodes, sea chest etc.

Planys Solution: The inspection was performed using Planys’ ROV Beluga equipped with high resolution camera, turbid water module, altimeter and depth sensor.

- Over 10+ minor anomalies were identified that included propeller blade chip, anode dimension check, rudder clearance check and sea chest inspection. Overall, it was found to be in order and dry docking was avoided successfully by the clients.

- Planys’ proprietary image enhancement algorithm were used to enhance the videos taken in the turbid waters

- All anomalies/defects were plotted against geo-tagged CAD drawing of every section on the Planys Analytics Dashboard (PAD) with localised click-to-view video feature.

- The report was given to the Class surveyor for further relevant action.

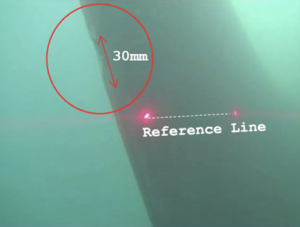

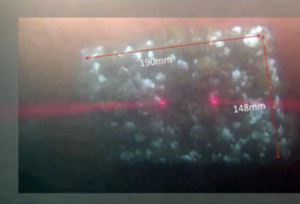

Images show deployment & setup of the ROV system and defects captured during inspection

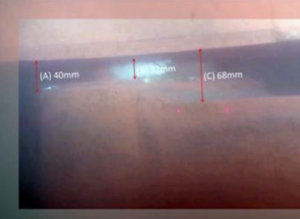

Images show dimensions extracted with Planys ROV of anode, thruster clearance and sea chest inspection