Culvert Inspection

Planys conducted underwater visual inspections of a culvert for local municipality in Rotterdam, Netherlands. Usually, the culvert would be emptied by erecting two coffer dams on either side and sending a crawler robot (humans were not allowed to go in due to safety concerns in confined space). These would be very tedious and expensive. A more efficient solution was desired for a preliminary inspection and Planys underwater inspection solution were deployed.

Scope of Work: Visual inspection of the culvert up to 70m length from each side.

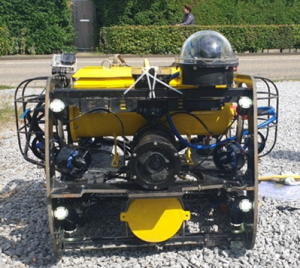

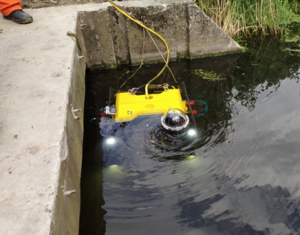

Planys Solution: The inspection was performed using Planys’ ROV Beluga equipped with high resolution camera (facing upwards) and depth sensor.

- The ROV system was deployed from the culvert entry point and the cockpit/command module was set up in a mobile van for the client o see the data live

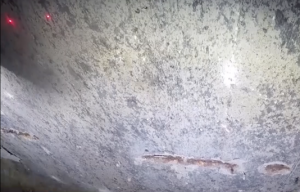

- Minor anomalies were identified like rebars exposed and minor cracks.

- Planys ROV pilot navigated the ROV expertly through the culvert collecting crucial data.

- All anomalies/defects were plotted against geo-tagged CAD drawing of every section on the Planys Analytics Dashboard (PAD) with localised click-to-view video.

Images show deployment & site setup of the ROV system during inspection of culvert.

Images show ROV visible from a small hole in the road & re-bars exposed in the culvert top.

“Hot-spot” map showing concentration of anomalies along the culvert with parallel views of front and top camera